The two most popular apparel printing methods are Screen and DTG (direct-to-garment) printing.

While screen printing is still used by many businesses to print custom t-shirts, DTG printing is gaining momentum due to the cost savings, unlimited colors, and eco-friendliness factors.

So the question is, which of these two printing methods should you use? And which one of these is more profitable?

In this post, we’re going to answer all of your questions about what DTG and screen printing are, the differences between them, the quality of designs produced, and the best printing method you can use for your business.

Let’s start with the major differences between these two custom printing methods…

What’s The Difference Between Screen Printing & DTG Printing?

The late 1980s were the heyday of the screen-printing craze. This printing method allowed customers to order large quantities of self-designed graphic shirts.

Back in the day, it was a revolutionary art form. However, there are some downsides to the use of screen printing.

For starters, the finished screen printed product has a bulky feel over the design, and the setup costs are a per printing screen basis. Secondly, production takes a long time and does not lend itself to intricate details.

Water-based ink takes time to absorb and then cure or set to move on to other processes like applying different print screens. This slowdown of screen printing is inefficient when pitted against DTG printing.

In contrast, DTG printers use a type of technology that supports high-volume direct-to-garment (or DTG) production even with the most detailed images or artwork.

For example, we at Marco Fine Arts use DTG based Ovaljet printers that are fast, allow for unlimited vibrant colors, and bring efficiency to the process. The result of which is a stunning array of high-quality products that feature gradient color changes without the buildup of ink.

Every printed shirt by Ovaljet printers looks amazing, and there’s no need to worry about screens or color limits with DTG printing.

Also, full-color printing is now achievable with the DTG method. That is why DTG printing is quickly becoming the de facto printing process for print on demand.

A Brief History of Screen Printing

There is evidence that screen printing first came from China as early as 960 AD, in which the ink was transferred onto fabric through a screen.

Other Asian countries adapted the methods to their own fabric coloring and modified the technique. Japan experimented with paper cut out stencils to create imagery that could then be transferred on textiles.

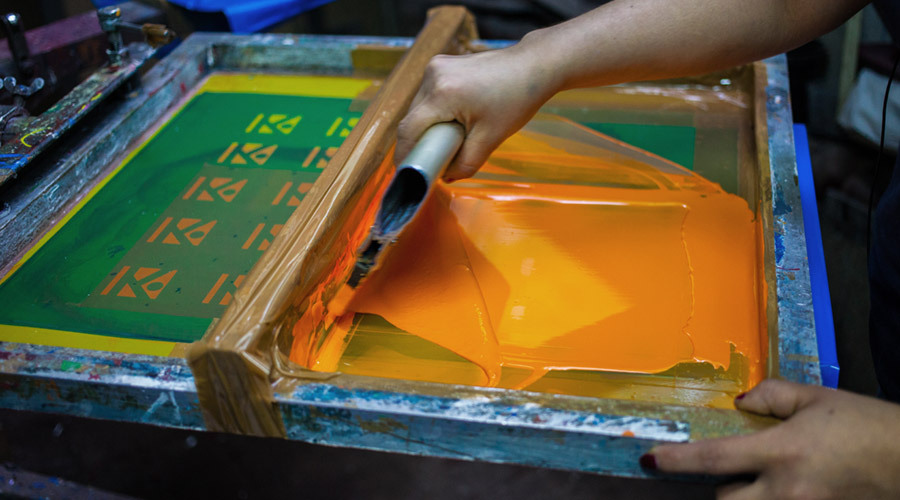

A simple mesh, made from human hair, was used as the go between the ink and the stencil. Tools such as hard brushes were used to force the ink through the mesh and onto the fabric.

Later on, in the 17th century, silk screens were used as a more efficient and elegant way of printing. Stiff brushes were used to pull the ink through, but color options were still limited during this period.

In the 20th century, the use of squeegees was introduced as a way to pull the ink through.

In 1960 a man by the name of Michael Vasilantone developed a rotary multicolor garment screen printing machine. Not only did it gain popularity at that time, but the machine’s origin and style are still used today. And this invention started the t-shirt revolution of custom shirt prints.

There have since been many advanced in printing, such as dye sublimation. This method is a technique where a special printer and heat press is used to dye ink applied on a shirt.

Is DTG Printing Good Quality?

By boosting the number of available color choices from nine to virtually unlimited, with DTG printing, you can enjoy photo-realistic renditions of designs.

But it doesn’t stop there! People now choose to combine photos with artistic additions for colorful graphics that are works of art rather than simple shirt prints. And DTG printers can produce amazing results on both light and dark-colored fabrics.

So with DTG, you never have to let a process limit your creativity.

The minimum you need to begin is a high-resolution digital image. The better the dpi and resolution of the image, the greater the final result will be when printed onto the shirt or garment.

Print on demand businesses can also offer custom product features to consumers like garment personalization by adding a name or phrase during the order process—the result, a custom experience that is achieved only with DTG printing.

Note: In DTG printing, the quality of the shirt you print on is important as it works best when printed on 100% cotton shirts. However, a poly-cotton blend can still result in a great quality print (if there’s higher cotton to polyester ratio).

Ovaljet Technology

The Ovaljet machines are based on the DTG printing method that uses a closed-loop technology where each garment moves through a series of automated stations. This provides for smooth DTG printing and production efficiency.

With Ovaljet printers, there’s no need for a team to work on shirts one by one. Instead, a single operator can move through the steps having total control from start to finish — which maximizes efficient order processing.

There are various DTG printer machines out there that do different parts of the process, but the closed-loop tech that OvalJet brings is the best all-around solution — and it’s a real game-changer.

Is DTG Printing Profitable?

Gone are the days when you had to create custom screens for each run. With DTG printing, you can directly communicate with the software that handles all the style elements of the DTG printer.

Whether your customer needs to make one shirt or a bulk order of 1,000 garments, it is easy to prepare for the run, fill the orders, and deliver high-quality apparel. So DTG printing is profitable to use, especially for service providers.

Here are two use cases where DTG printing can be very profitable:

- Artists and designers can use this technology to supplement their income or create a career out of reselling graphic shirts in less time.

- Small businesses can use sample prints to get one or more final production proofs for their project to show to their customers.

Combine the two points, and you have a profitable product.

The added ability to allow customers to customize their printed projects can further increase the profit margins. Selling online with a simple form for personalization ensures what the customer fills out is what they get.

Since the items are created on-demand, adding a name at the time of printing doesn’t change the paradigm one bit, but the end result is more money in your pocket.

There are other niches other than t-shirts where you can use DTG printers for profits, like a stretched canvas, quilts, custom pillowcases, custom wood prints, and more.

Who is DTG Printing Suitable For?

Whether you sell online or offline, DTG printing is excellent for everyone!

Businesses, organizations, non-profits, fundraisers, charities, and teams all use DTG printing products for various purposes, including:

- advertising

- demonstrating a cohesive look for everyone on the team or company

- reselling

- raise awareness for a cause

- giveaways at trade shows

- sporting events for bulk giveaways

In the 1960s, people would design political statements on their shirts, like the widespread use of revolutionary Che Guevara.

Teams and organizations have to mass-produce their shirts and apparel to help represent them when they’re participating in or hosting their events. The needs of an event have to be quick, and DTG printing offers just that. All that’s needed is a properly formatted digital file.

How Long Does The Print Last?

Sure, DTG is fast. But, is it also durable? After all, nobody wants disappointed customers who complain about color washing or fading.

On-demand print services are only attractive when the customer is happy with the product and returns. In addition to a low price, the quality of the printed work has to speak for itself.

The results you get from DTG garments are long-lasting and can smoothly go through hundreds of washes. The printed garments may vary from style and ink absorbency, but the print result is undeniable.

To make sure you produce the highest quality prints, you can follow these tips:

- Work with fabrics that soak up the ink

- Use cotton cloth for long-lasting prints

- Invest in the right high-quality inks

It can be tempting to cut corners, but it’s not worth it.

Note: You can use pre-treatment of fabrics to increase the durability of the prints.

How Much Direct-to-Garment Printing Costs?

Because of the efficiency, DTG is always cheaper than screen-printing. This is perhaps the most critical selling point.

Some DTG printers might charge more for detailed designs as they know that this is not something that works well when screen-printing, which gives the new method a decided edge.

Others reduce their costs because they don’t have to require order minimums, which can dramatically increase the impulse buy.

As a result, operators share the love and pass on their savings. Pricing is important, but the value that DTG brings is also in speed, efficiency, and turnaround time. Using the right combination of price and value will close more deals.

That is why many people now prefer the OvalJet printing method!

Frequently Asked Questions

What is DTG printing?

DTG printing, also known as direct to garment printing, is when a digital image design is printed onto the garment. DTG printers offer a more efficient process than screen printing and have benefits like cost and time saving, efficient production, and the requirement of only a single operator per machine.

What is a DTG printer?

DTG printers are like giant inkjet printers that print directly onto garments, fabric, textiles, and apparel. The output is much higher than a traditional applied screen printing process. Operating a DTG machine is much simpler than a screen printing counterpart. You are not limited to a maxed-out screen printer, and you’re free to use unlimited vibrant colors in your work and achieve the look you intended. Colors such as white, black, and a variety of shades thereof really do pop on the garments they’re impressed on thanks to the fast drying application technology.

How does Print On Demand and DTG Printing Work Together?

The business of print-on-demand has exploded over the past few years. As the name suggests, this print type allows people to start a side hustle to sell their designs on many platforms such as Shopify, Etsy, Amazon, and other popular marketplaces. Print on demand (POD) includes many items for sale, such as shirts, canvas prints, wallpaper, pillows, and more. With DTG printing’s help, businesses can keep up with the volatile product demands without worrying about order minimums.

How Durable is DTG Printing?

DTG printing is a terrific method for producing long-lasting, durable prints on clothing, and textiles. You’ll find this to be good as, if not better, than large retail and other outlets and fashion stores. The value that DTG printing offers has allowed small business owners to level the playing field when measured up against the big-box counterparts. Even after many washes, your DTG printed clothes look great.

How Many Shirts Can a DTG Printer Print?

The OvalJet can print up to 240 shirts per hour with a single operator. Roughly 1920 per day (and approximately 700,000 per year) can be produced by one machine. DTG printers are designed to meet the demand for high volume printing.

What’s the Best T-shirt Printing Method?

When it comes to printing for profit, you want to look for quality, turnaround time, and durability. Two out of the three boxes can be checked off for silk screen printing, but it lacks speed. No doubt screen prints are of high quality, but they are limited to specific colors and are very time consuming and labor-intensive. With DTG printing, prices can be kept low as DTG printers require minimum preparation and setup, which results in speedy turnaround times (as little as 24 hours).

What Can You Print on with a DTG Printer?

Other than garments and apparel, there are a few items that you can print directly on. Certain DTG printers can also print on stretched canvas, murals, custom pillow covers and cases, quilts, and other direct to fabric-related products. These printing methods open the doors of possibilities for your next project.